In this post I compare all three versions of my light weight structure experiments, with a couple of pictures an descriptions that were not given in the video below:

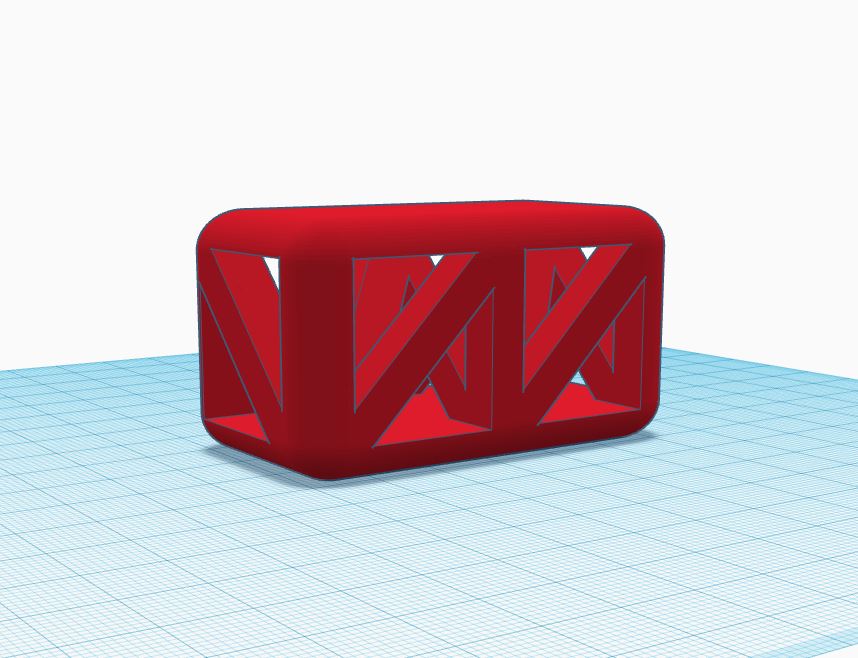

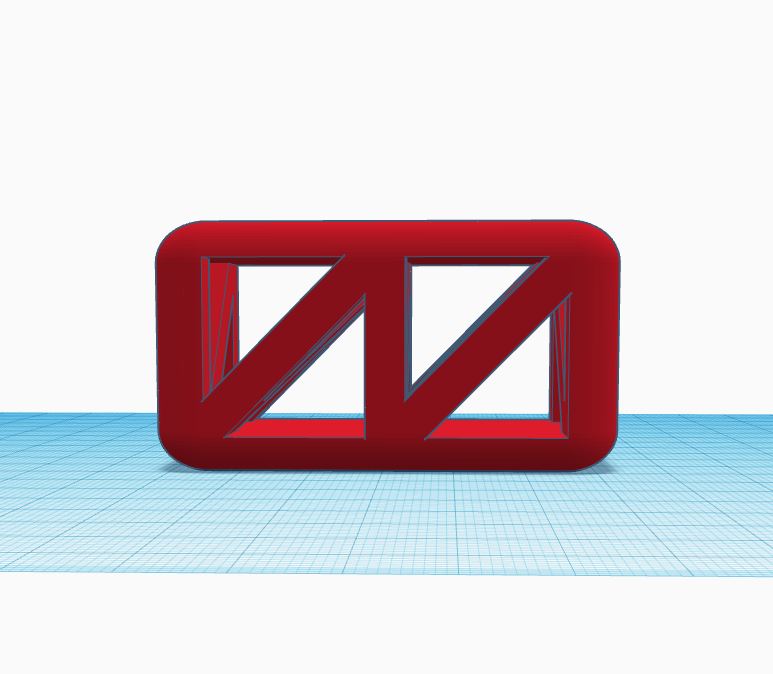

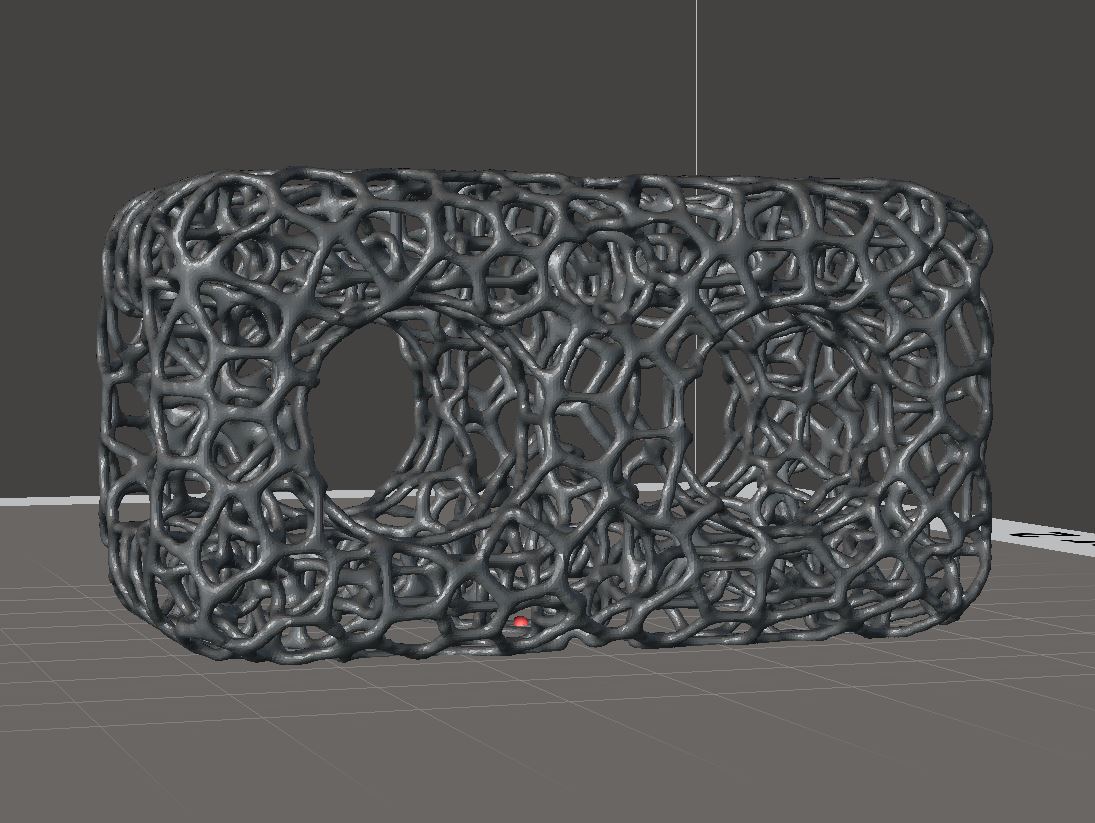

Version 1 had no roof and floor holes and that created the problem for the printer, also, I was printing the PLA at 200 degrees. I learned that lower temperatures are better for bridge structures. Download both files on Thingiverse.

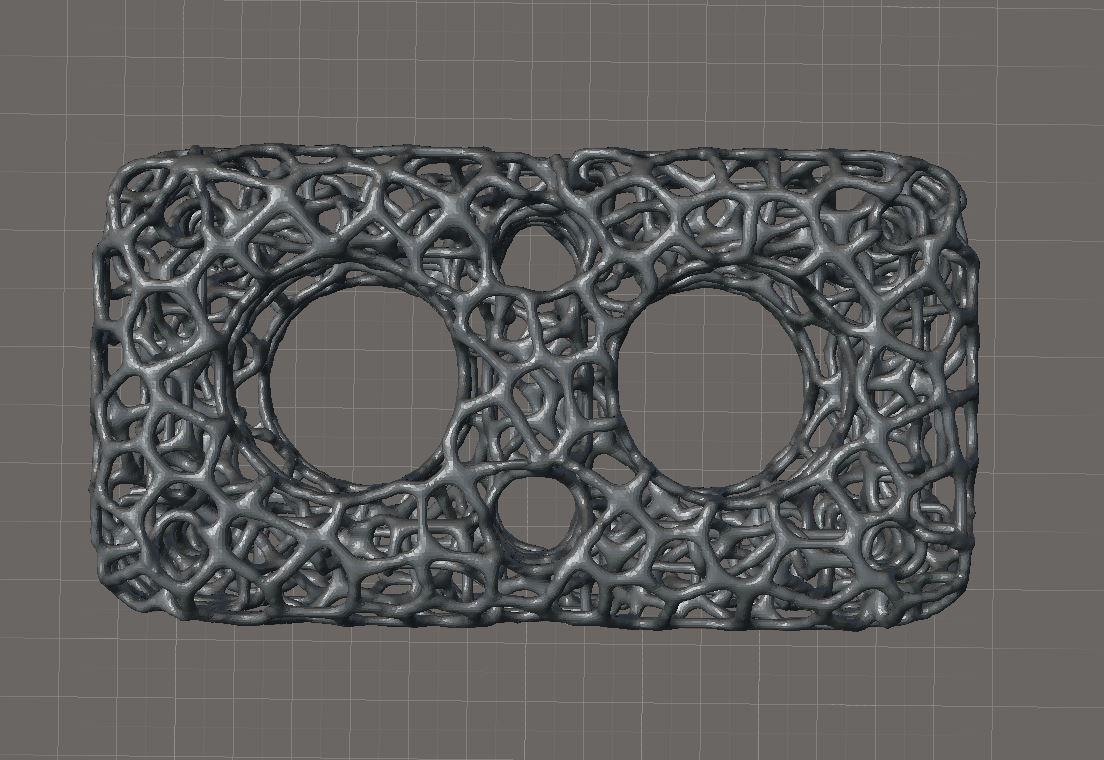

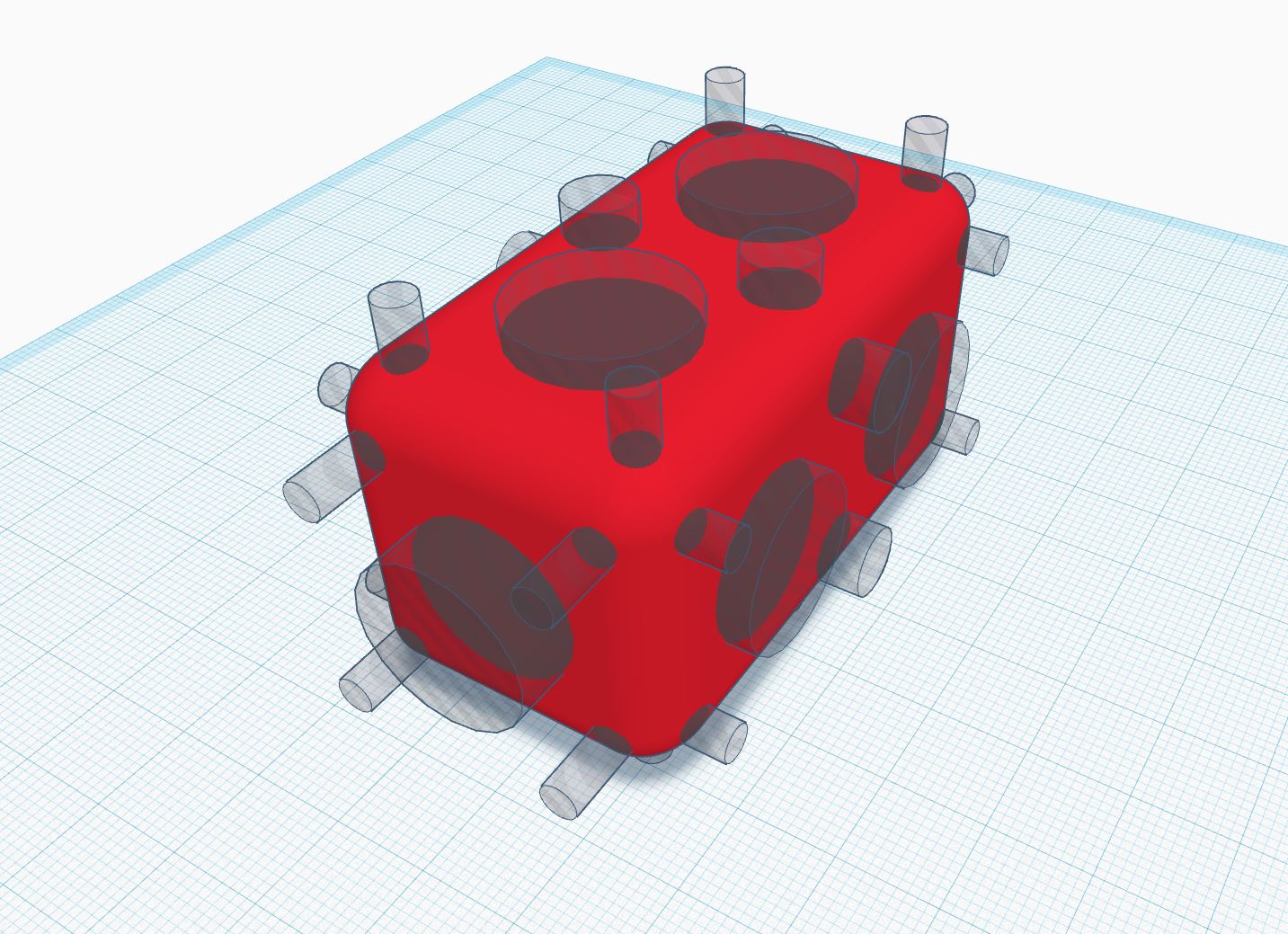

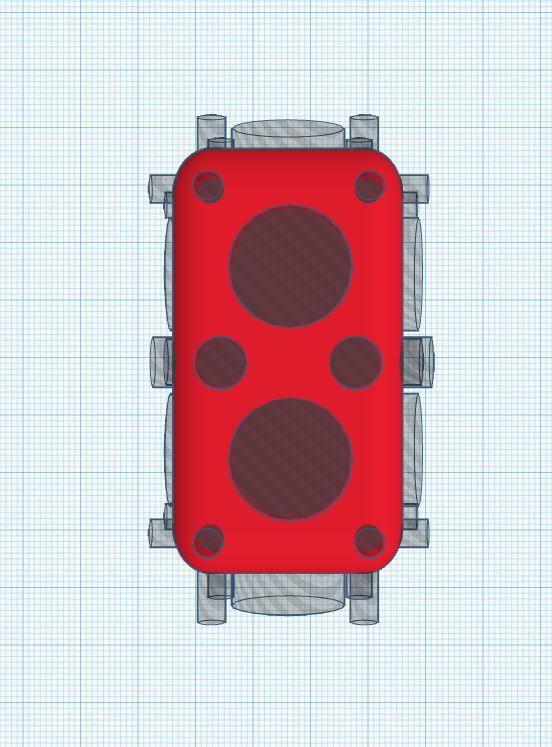

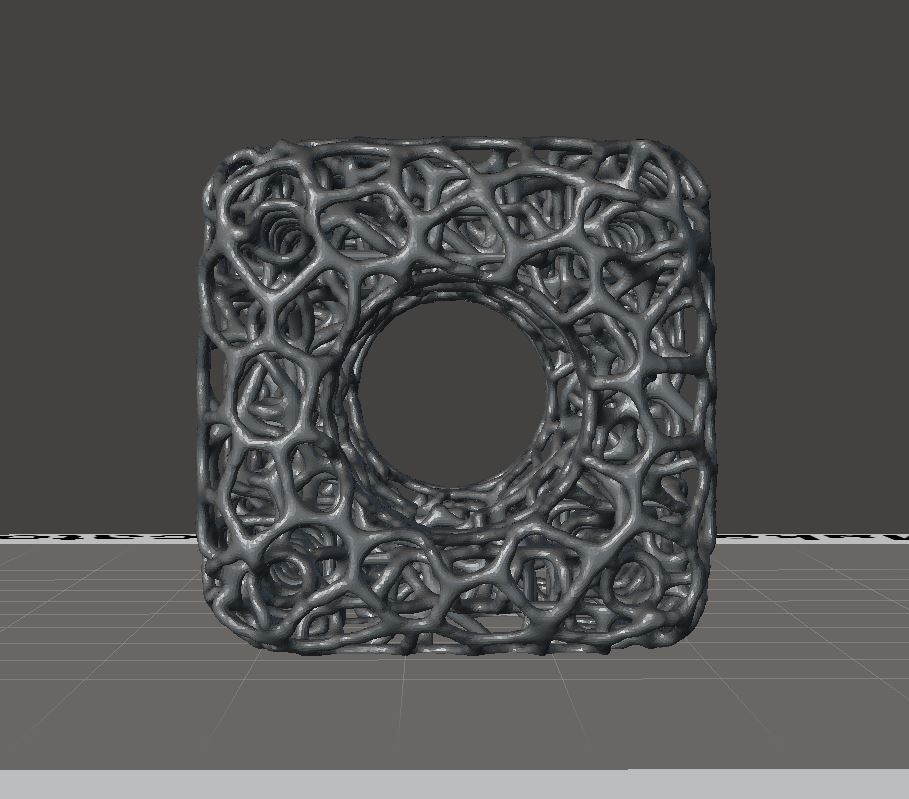

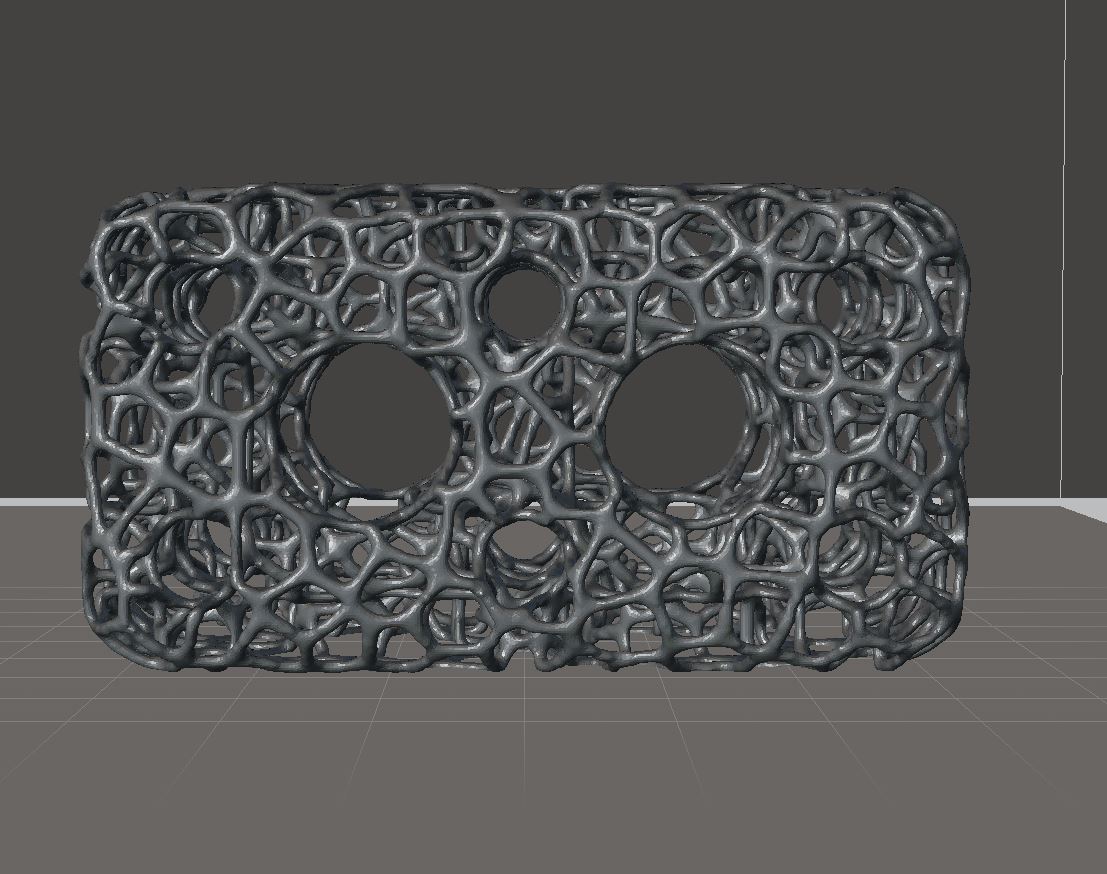

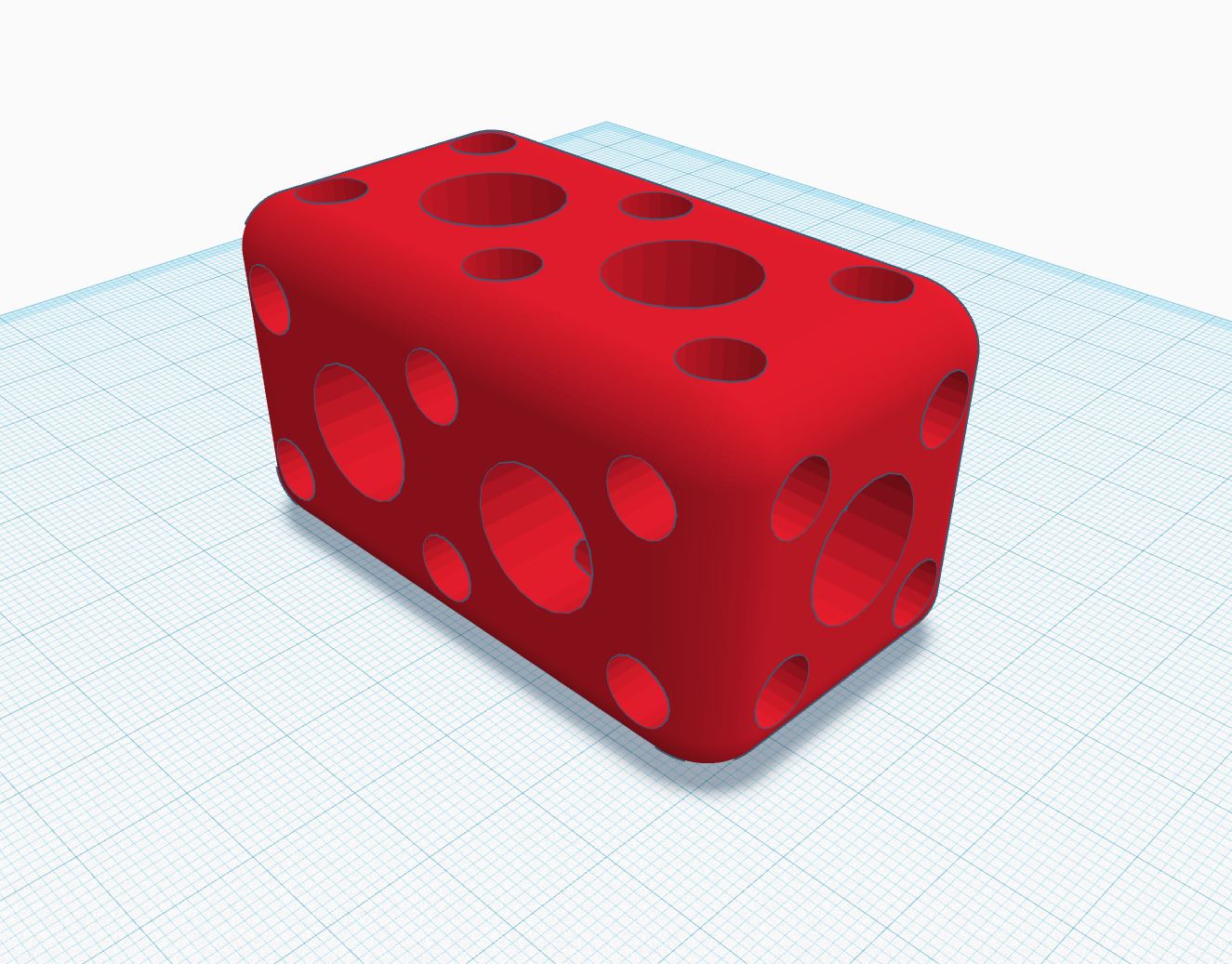

So, for version 2 I decided to work with round holes in all three planes, cylindric holes always yield a more organic appearance compared to triangles / prisms and I want to get more organic looking structures. Download version 2, solid and vorony version on Thingiverse.

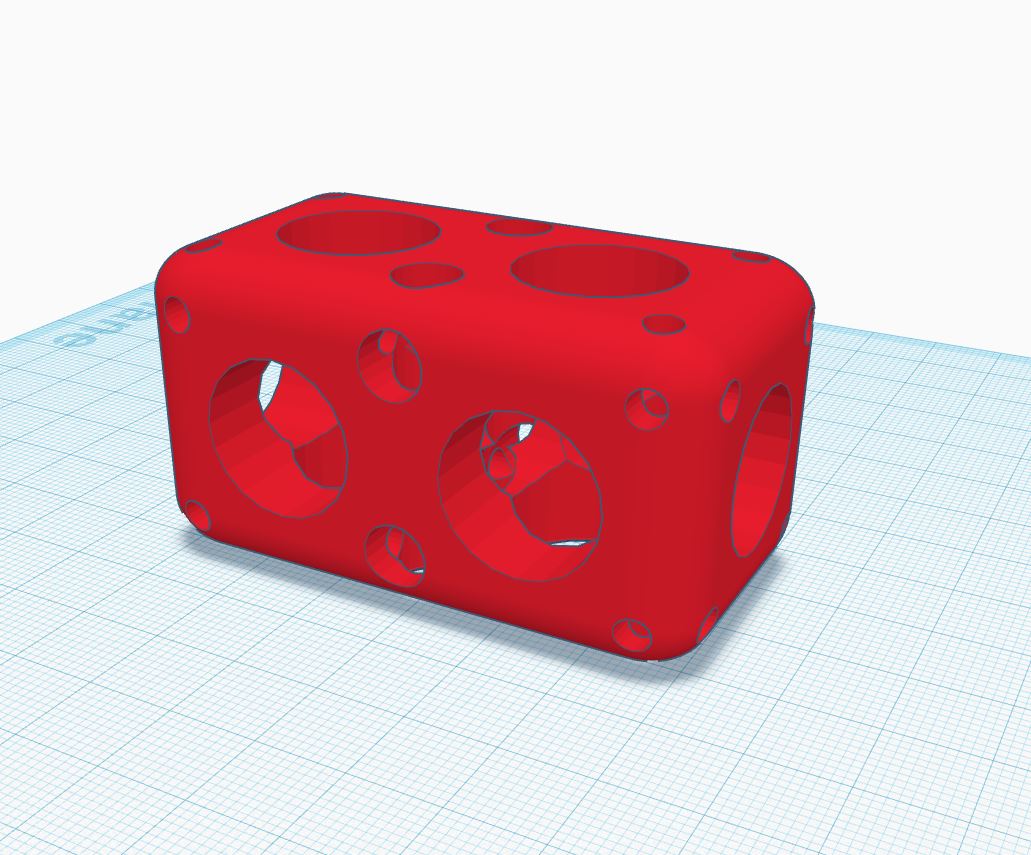

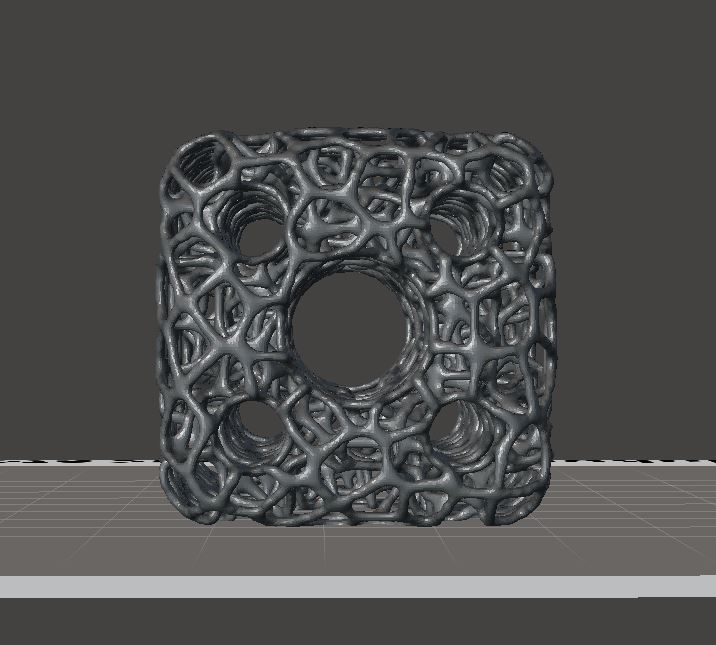

Version 3 is a refinement of version 2 in that the smaller holes are bigger in diameter to better distinguish them better from the Vornoy holes generated automatically. Also, a greater diameter yields more surface to add the organic structure. Finally, I reduced the center holes to get a better average “wall” thickness, i.e. the distance between a hole and another hole or the sides from the box. In this way, the printer had a better chance to actually realise the Voronoy holes between the cyclinders.

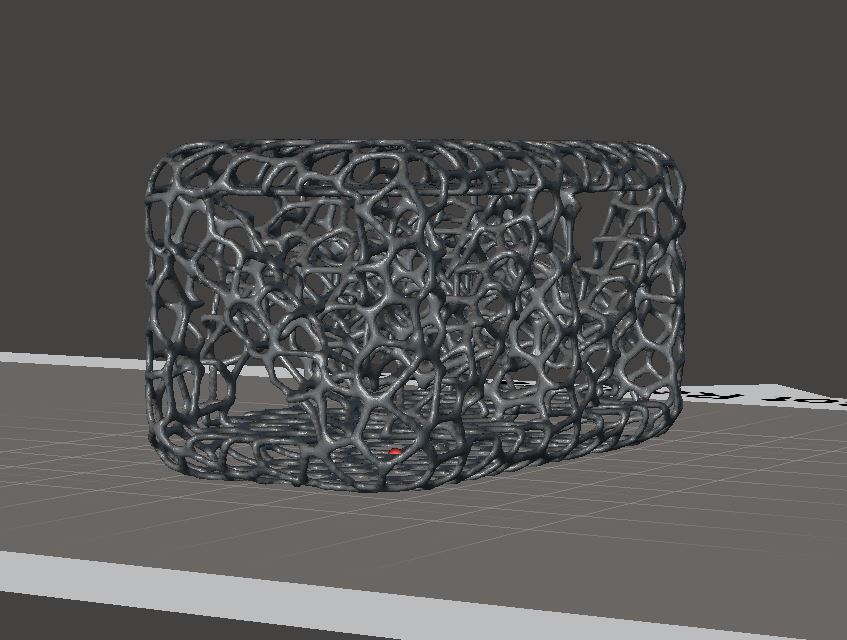

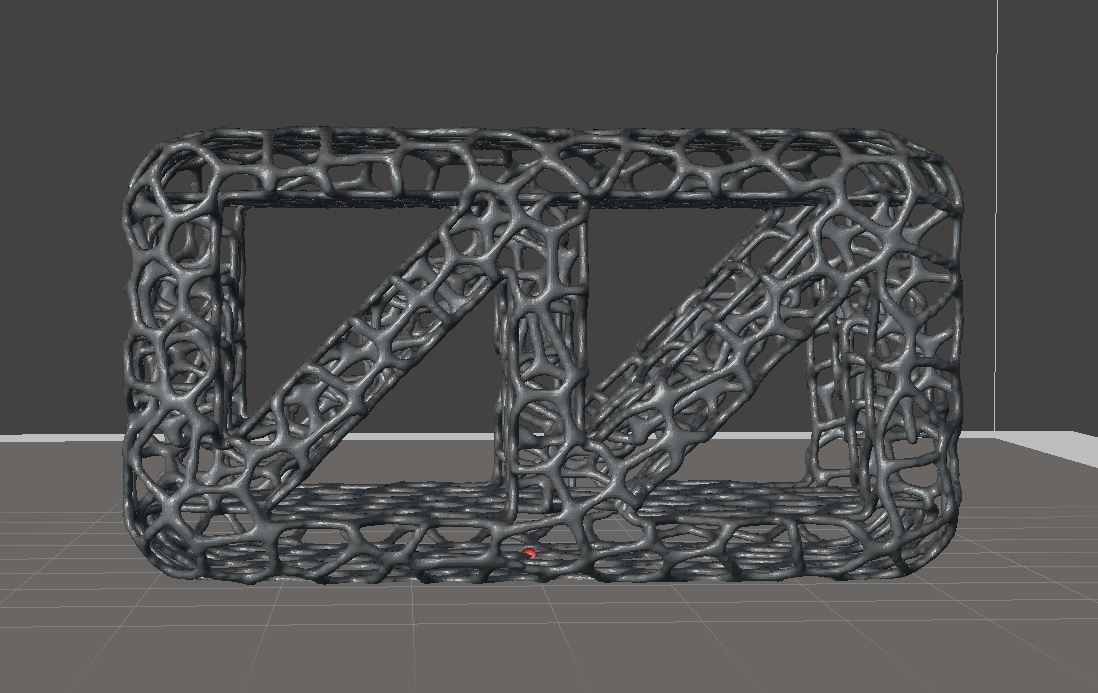

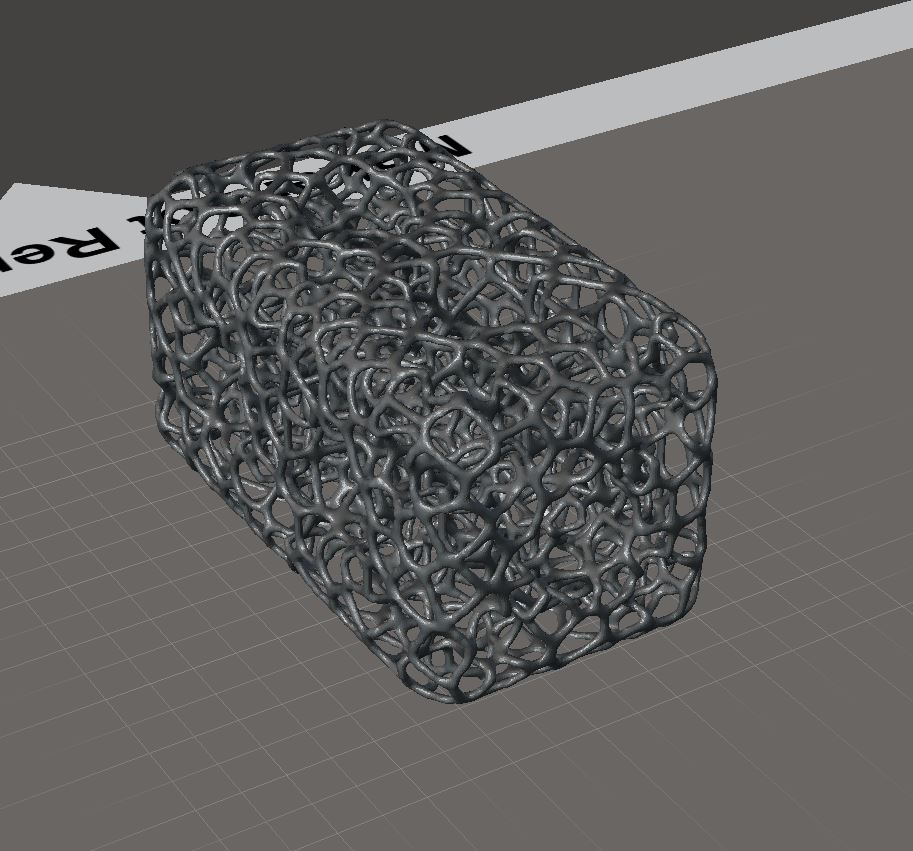

Finally, I produced the Voronoy version with a thicker structure, meaning that the lines were thicker and ideally the printer has a better chance to “find” them again in the next layer:

Final versions for download here.

Learnings when printing:

I also reduced the printing temperature to 190 degrees from layer 3 on. The first layers I printed with 200 degrees to allow for a better sticking to the heat bed. I changed the bed to glass and used glue stick. These delicate structures have only a couple of touch points with the headbed so it is of outmost importance to have them sticking well. The servo housing shown in the end of the video was printed on pure glass without glue or spray, but the organic structures need more attention…