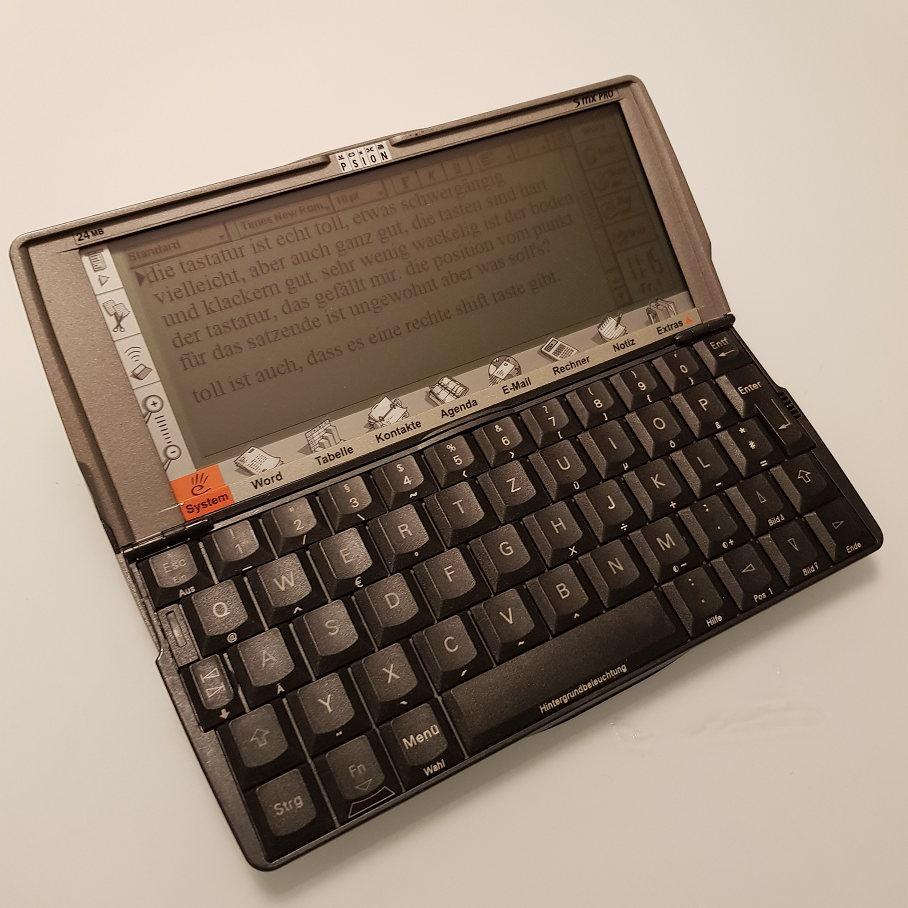

I admit: I love how home computers from the 80ies were booting up in no time. I’ve been trying to optimise the boot up time for Raspberry Pis for some time but I don’t get very far. I’m also fascinated by baremetal implementations where hardware is used for a single purpose and also works on an instant. Micropython is a nice idea inbetween as it is a “high level language” and still runs without too much overhead on very small resources.

Another thing that I’m dreaming of is to be able to write software on the go using a minimal dedicated device. My prrevious attempts comprise:

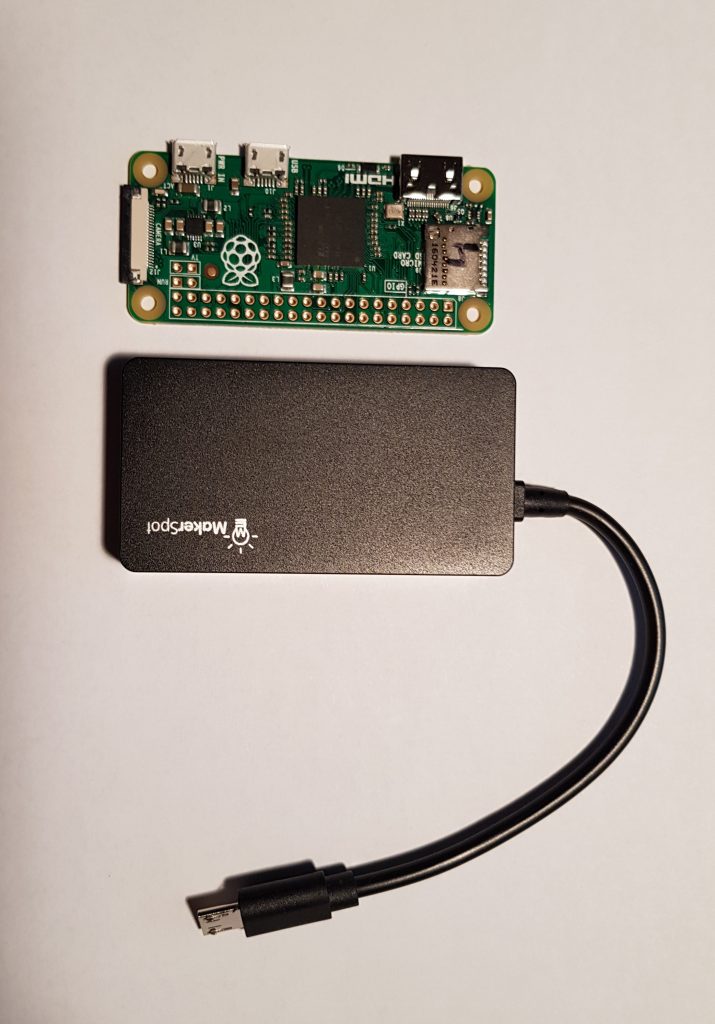

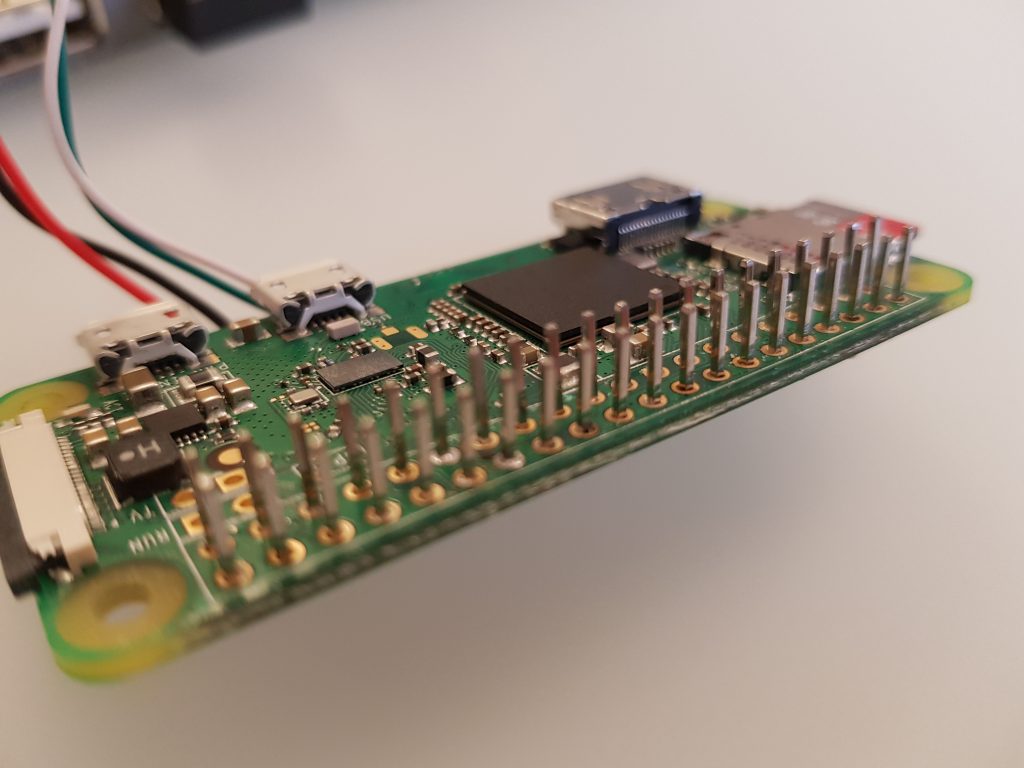

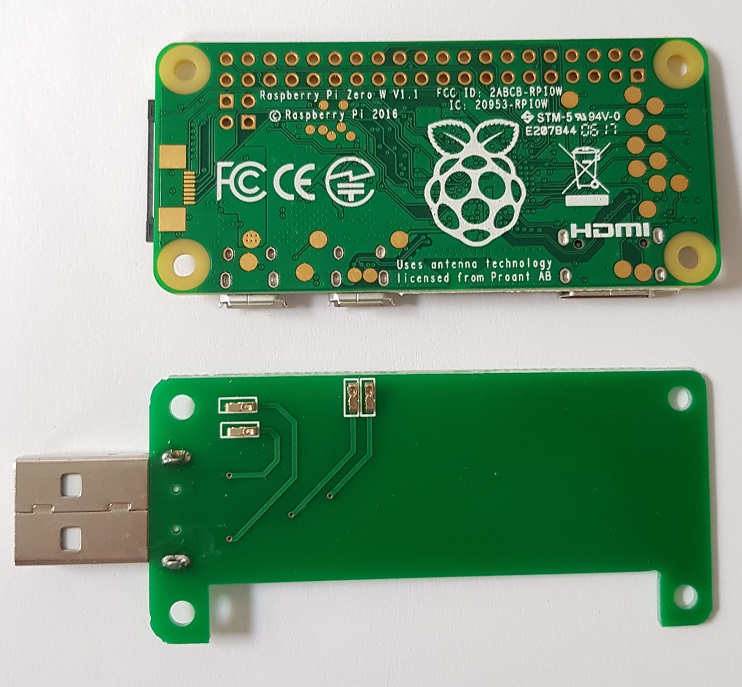

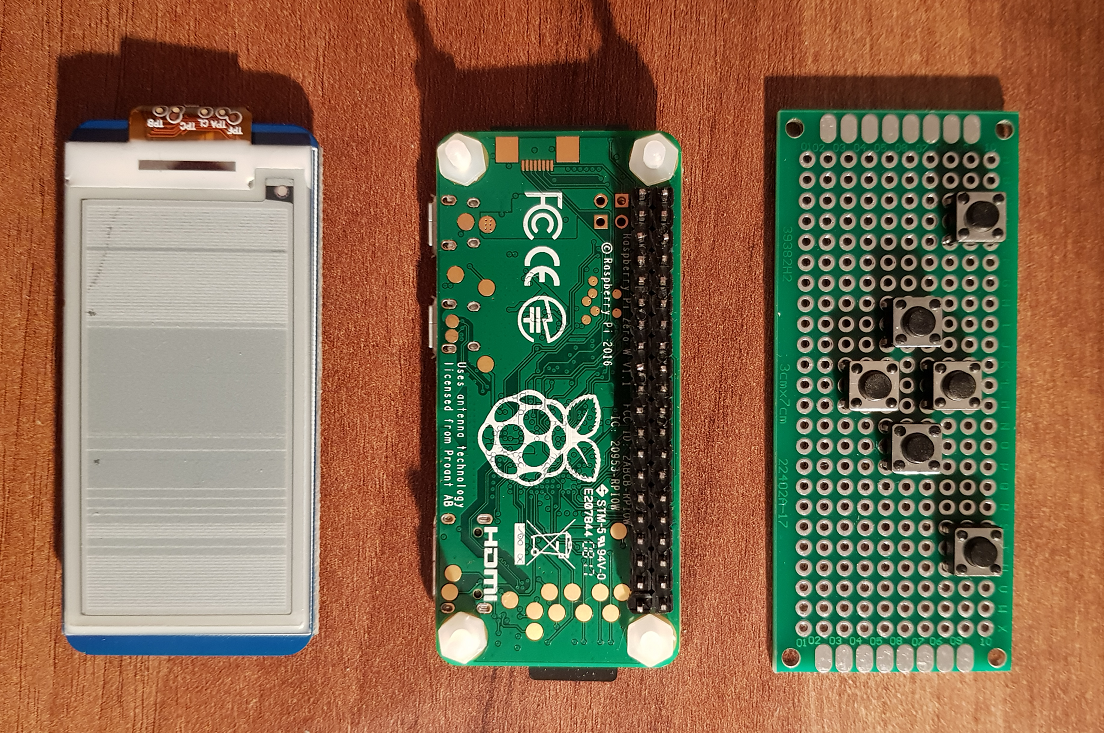

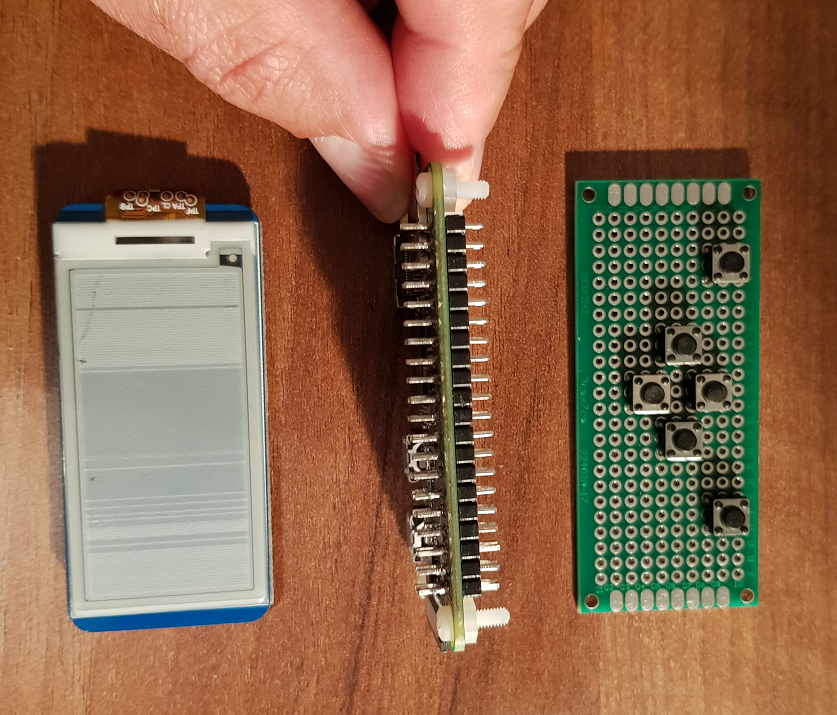

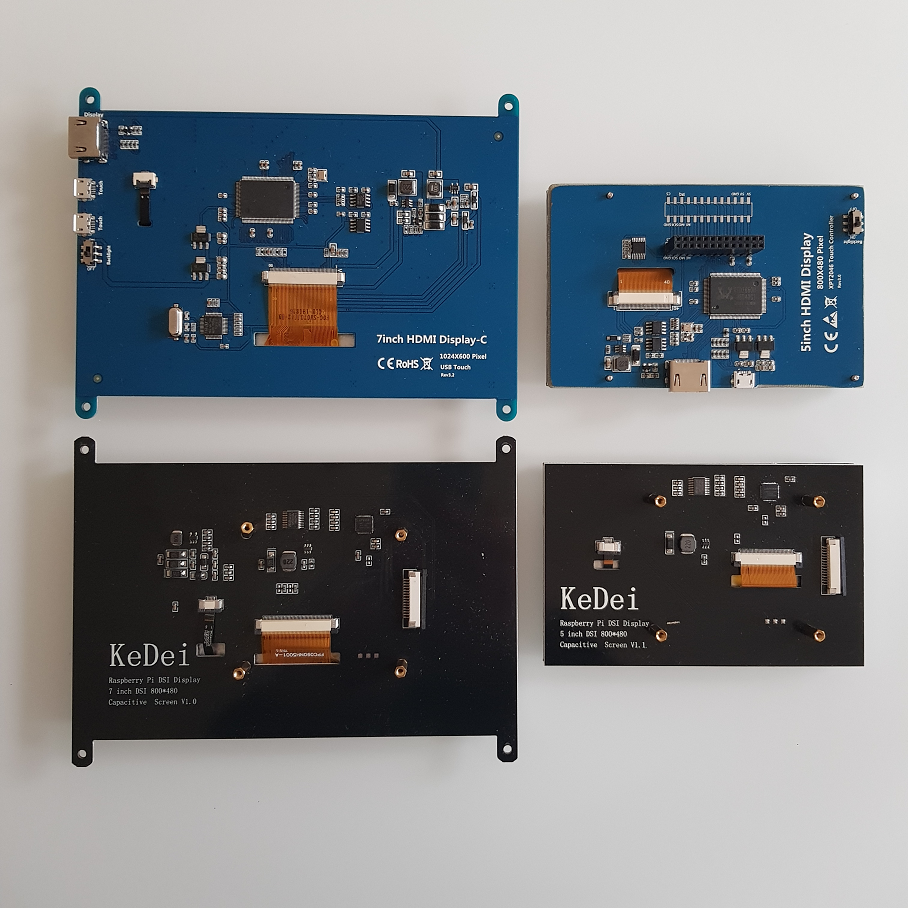

- The StickPi (super small Pi Zero with an epaper display and no keyboard for ssh access from a notebook, no battery)

- The PocketPi (battery powered Pi Zero, 800×480 4in Hyperpixel screen incl a small keyboard)

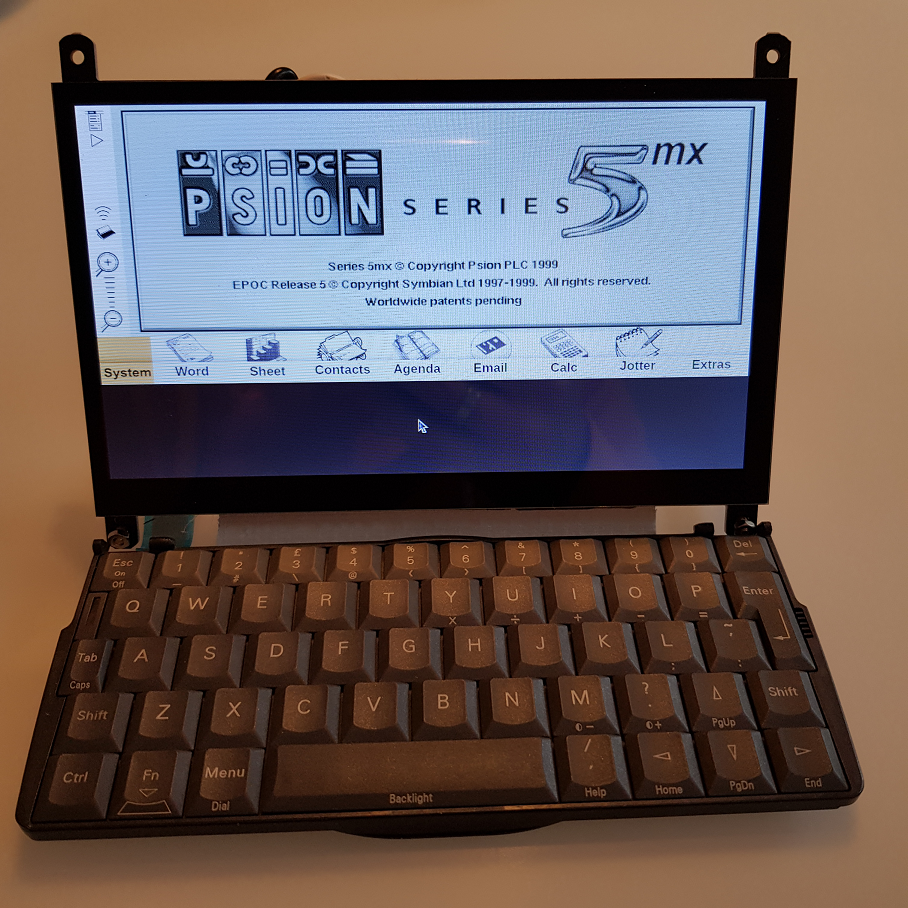

- Last week’s PsionPi (battery powered Pi 3a+, Psion 5 Series keyboard incl Arduino keyboard controller and a 7in 800×480 screen)

- And a yet unpublished 5in screen slate design.

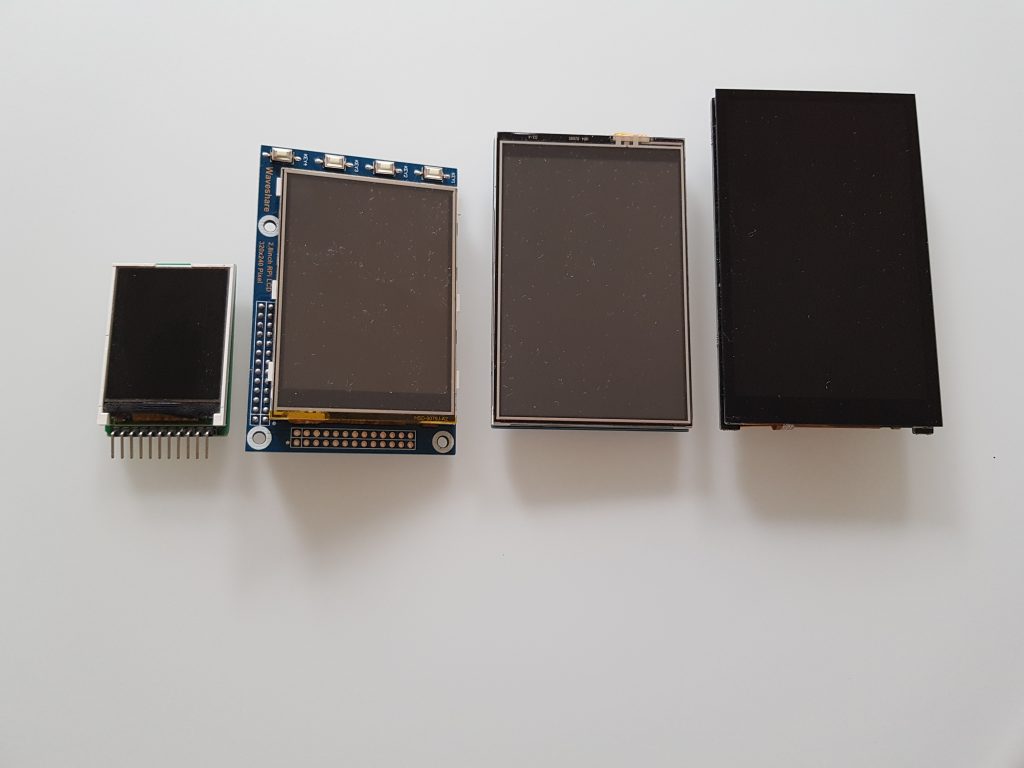

All these are Raspberry Pis in different formfactors. When the Adafruit PyPortal Titano was released, I was immediately in love as it comprises a lot of nice hardware and a 3.5in 320×480 screen that I also had evaluated for the PocketPi.

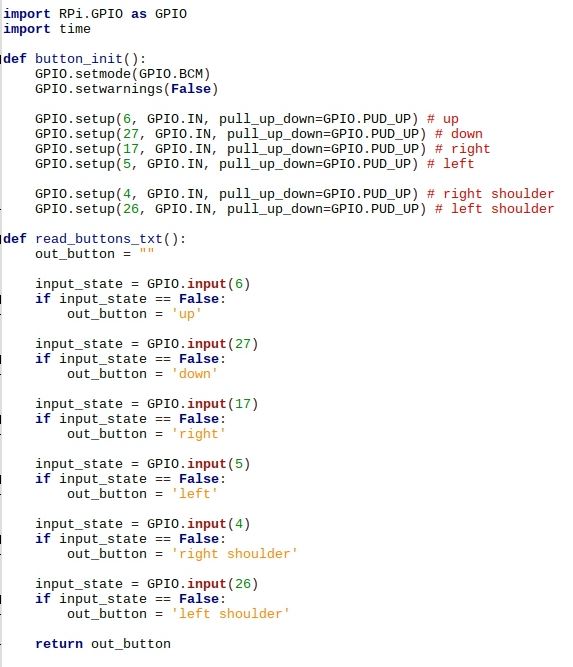

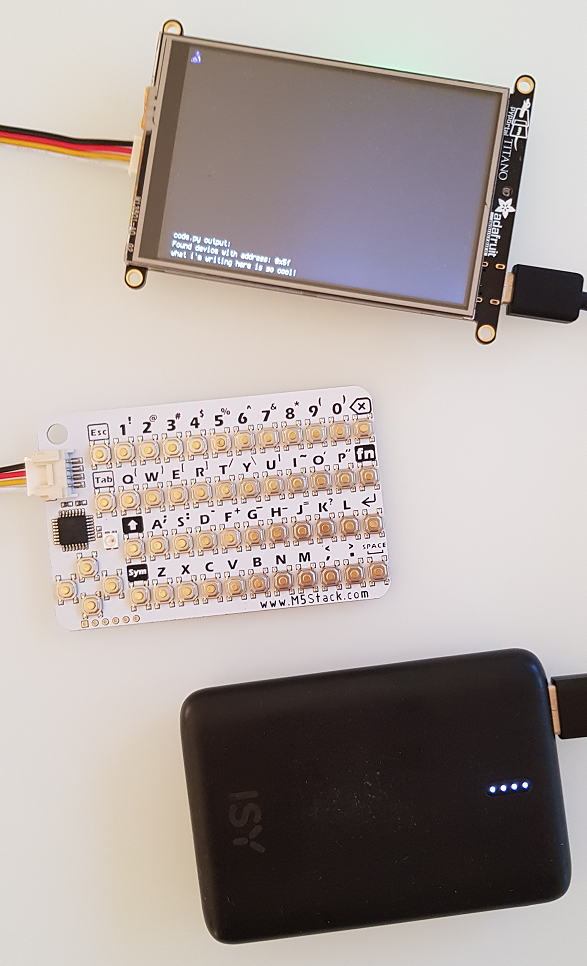

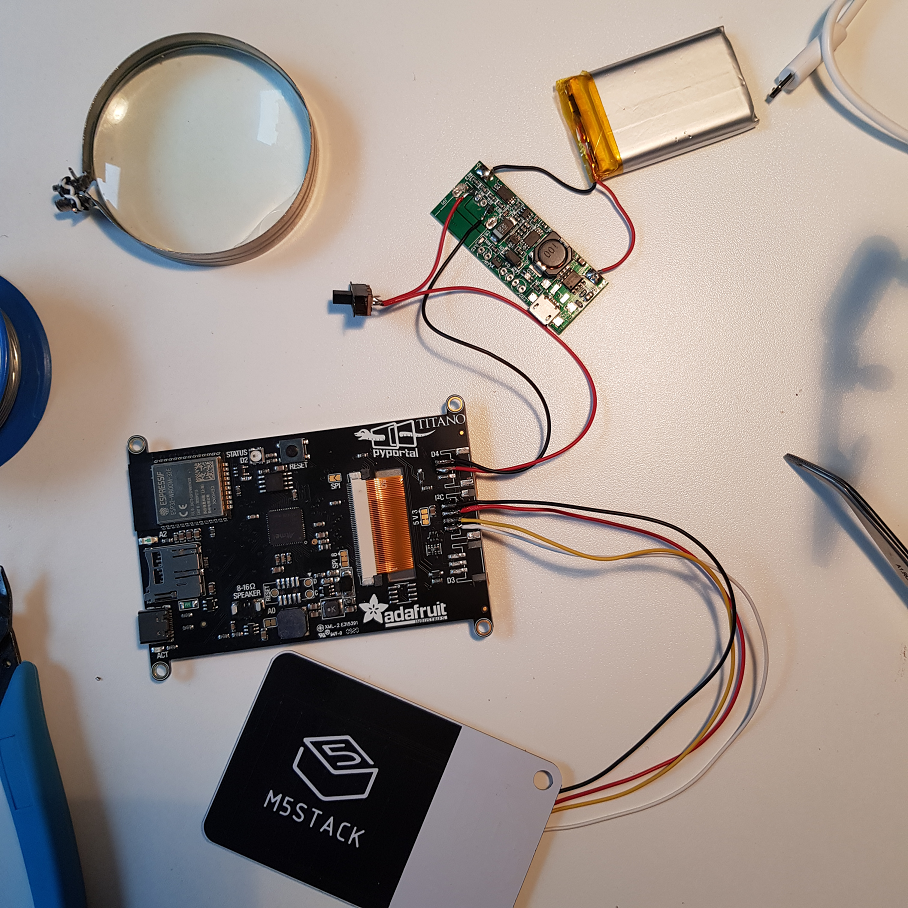

I also recently came across the hardware line of the M5Stack and their super-small and cheap I2C QWERTY keyboard caught my eye. The keyboard itself is also using an Arduino to read the key-matrix and translate the key presses to externally digestable code. So, this is my third Arduino-controlled keyboard (the recent mechanical keyboard and last week’s PsionPi). The PyPortal also has I2C connections, so let’s try it out:

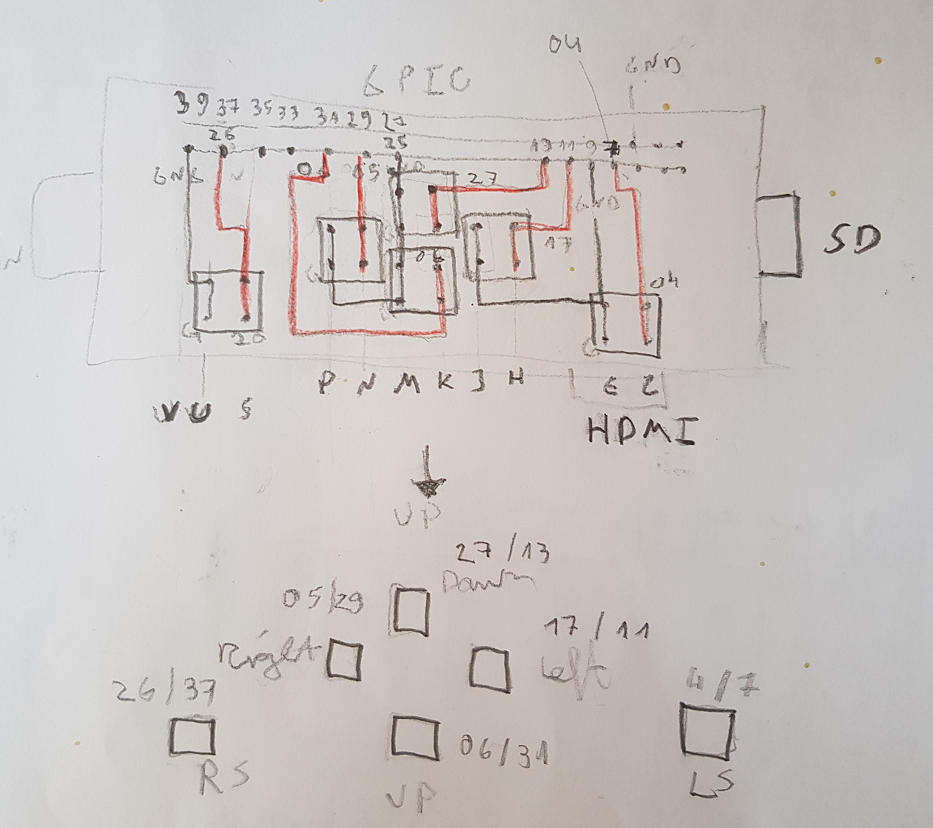

So the first thing wanted to try out is to connect the two and see if I would get use the keyboard to enter text without a host computer or a USB keyboard. The keyboard is available at 0x5f and you just need to translate the keycodes to letters, certainly you need to translate delete, backspace and return keys to the right “actions” on screen, which kind of results in a minimalistic text editor:

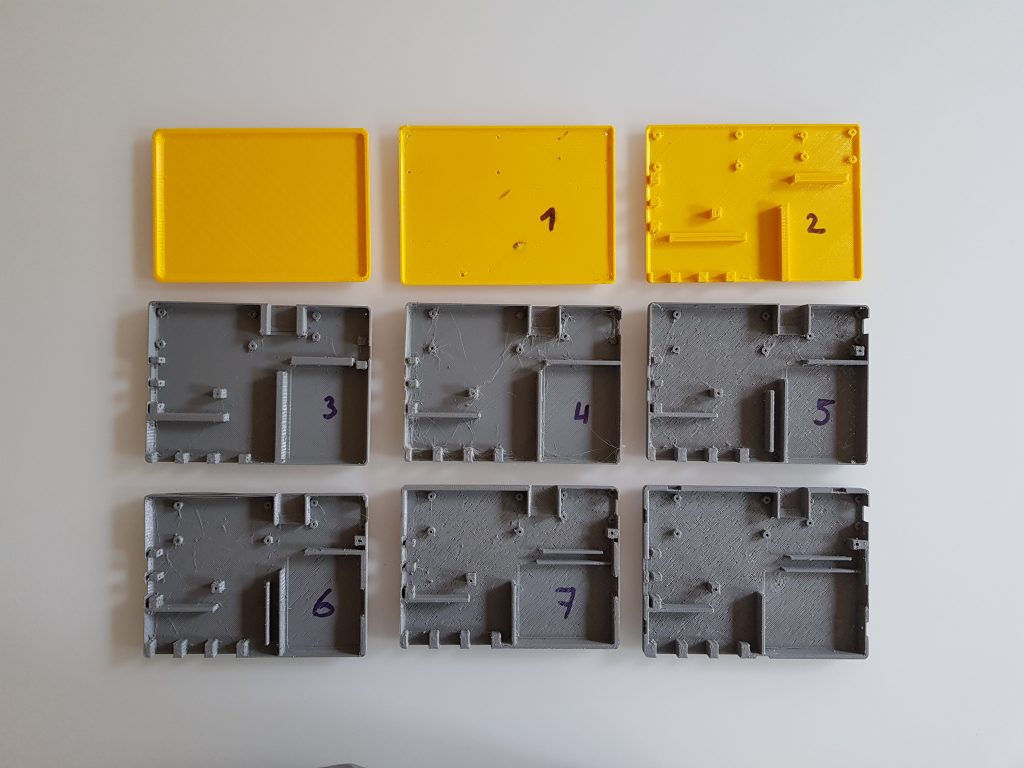

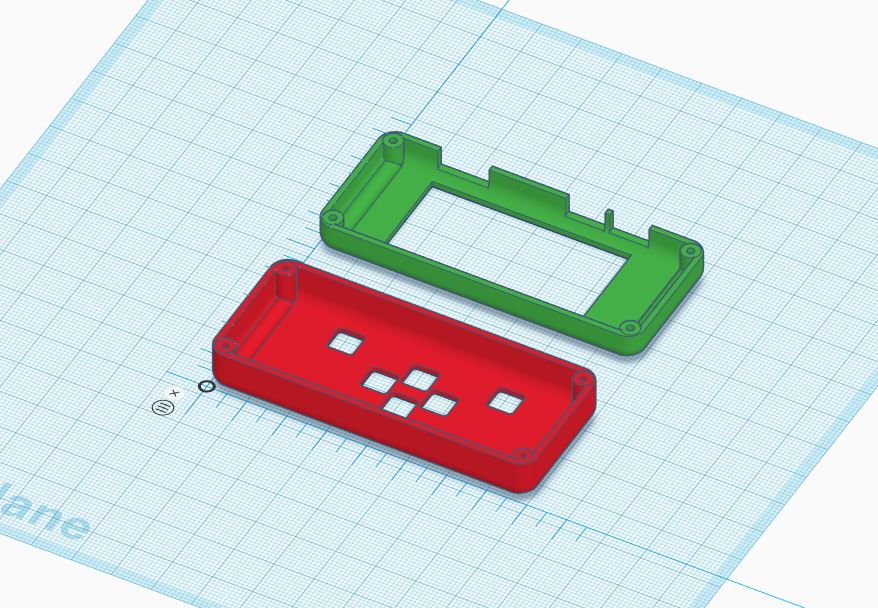

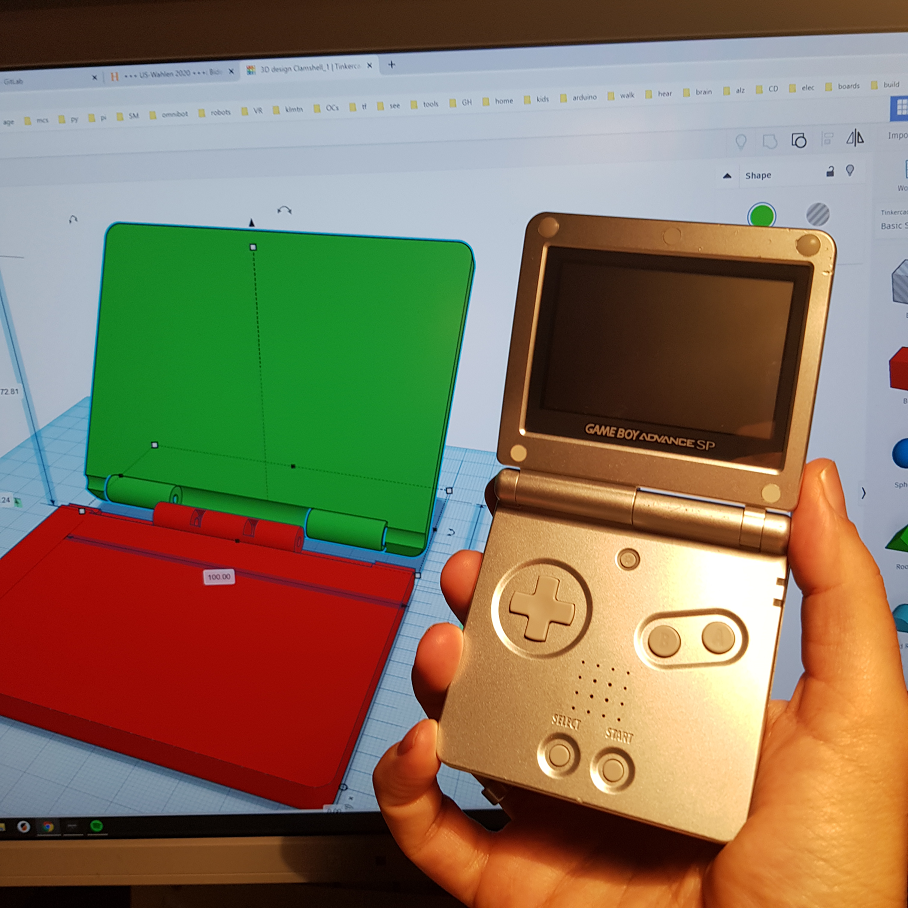

Next thing was to design a case. I never ventured into hinge design, so I wanted to keep it as simple as possible just to get started and to see whether writing code is fun or not. So I started with a slate design:

Actually, the Casio pocket calculator is a clamshell design already, but my beloved Nokia E61 is a good sparring partner in terms of design. So the black base plate is a 125x100mm design which is kind of nice, it wouldn’t get much smaller than this. I got bored with the slate immediately when it finished printing…

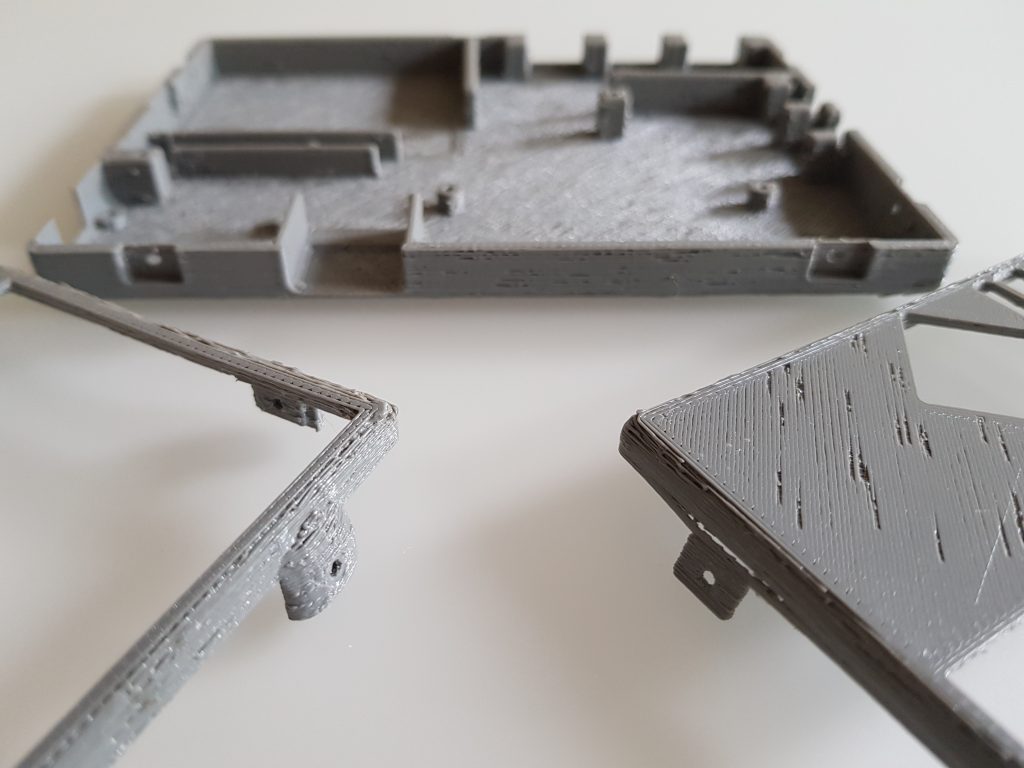

On the other hand, what was really a logical next step in terms of form factor was the clam shell design and when I had an old Gameboy Advance SP in my hand, I felt that I need this nice sound when closing and I wanted to have a computer like this. Back to Tinkercad:

Now the baseplate has 100x80mm and the hinge is working really well. I also added magnets on all corners to keep the states stable but they are not strong enough and take up valuable space.

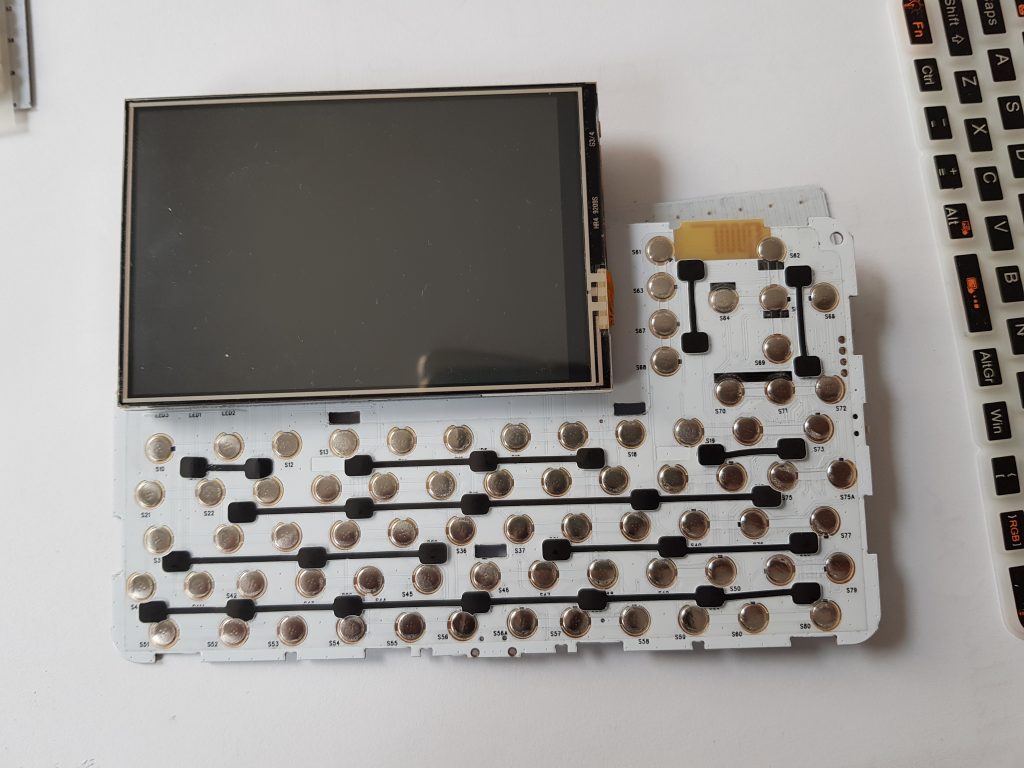

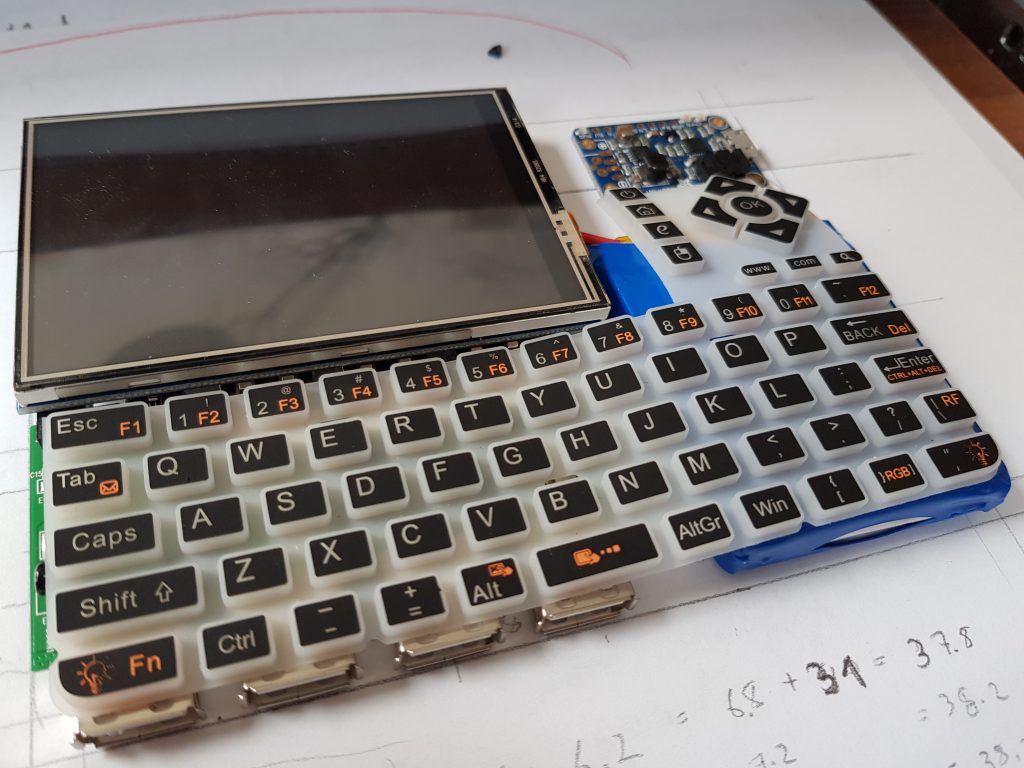

Just for fun, I pulled out my old screen from the earlier PocketPi iterations:

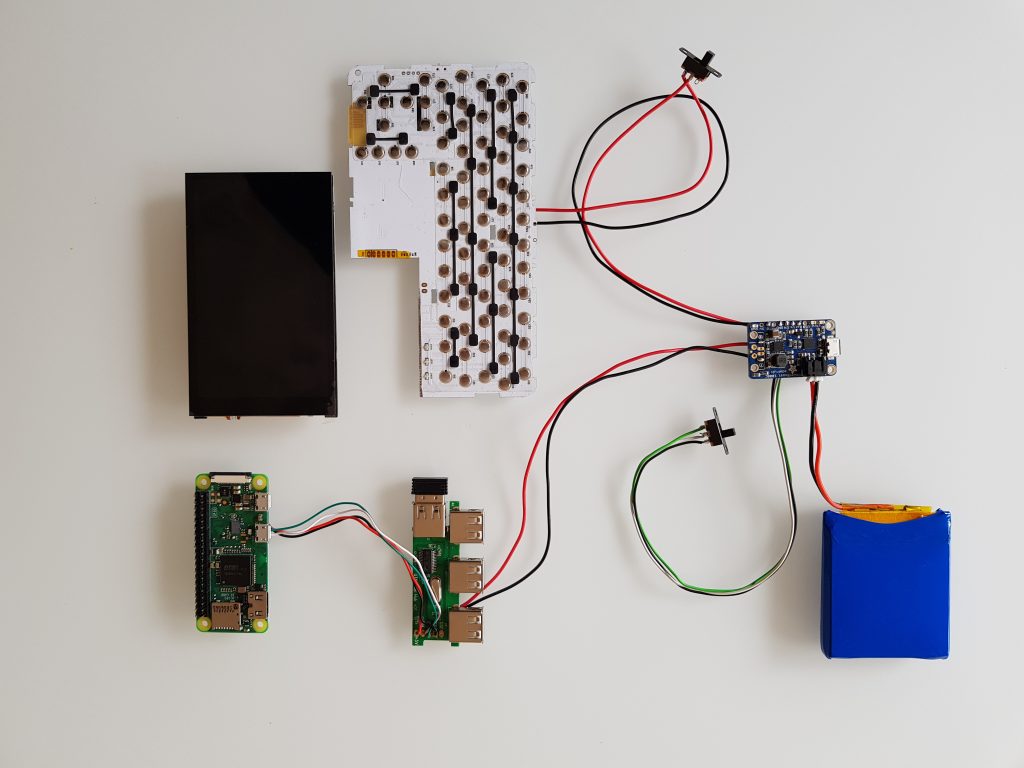

To make this usable, you’d need to add the Pi Zero underneath and power both with a battery plus connect them somehow (not via Wifi 😀 ).

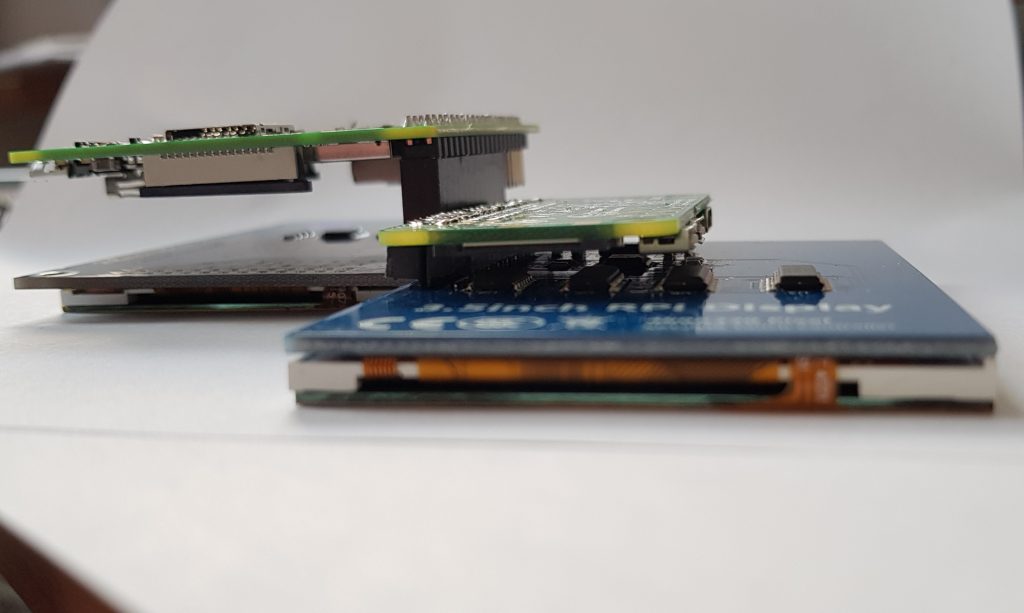

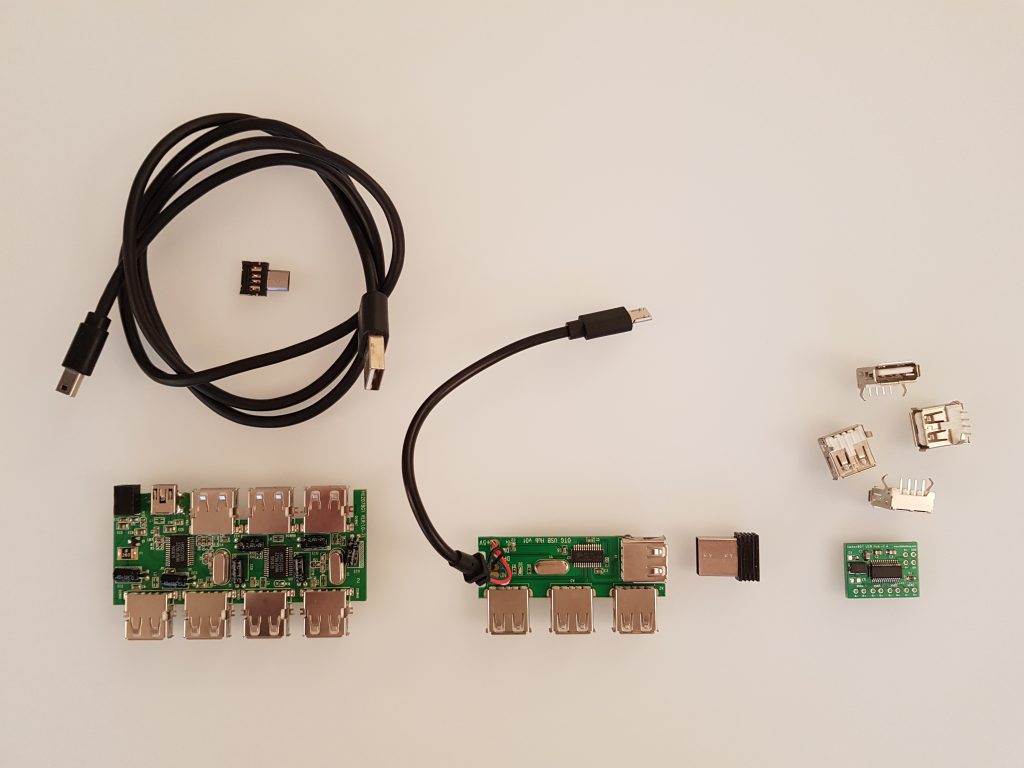

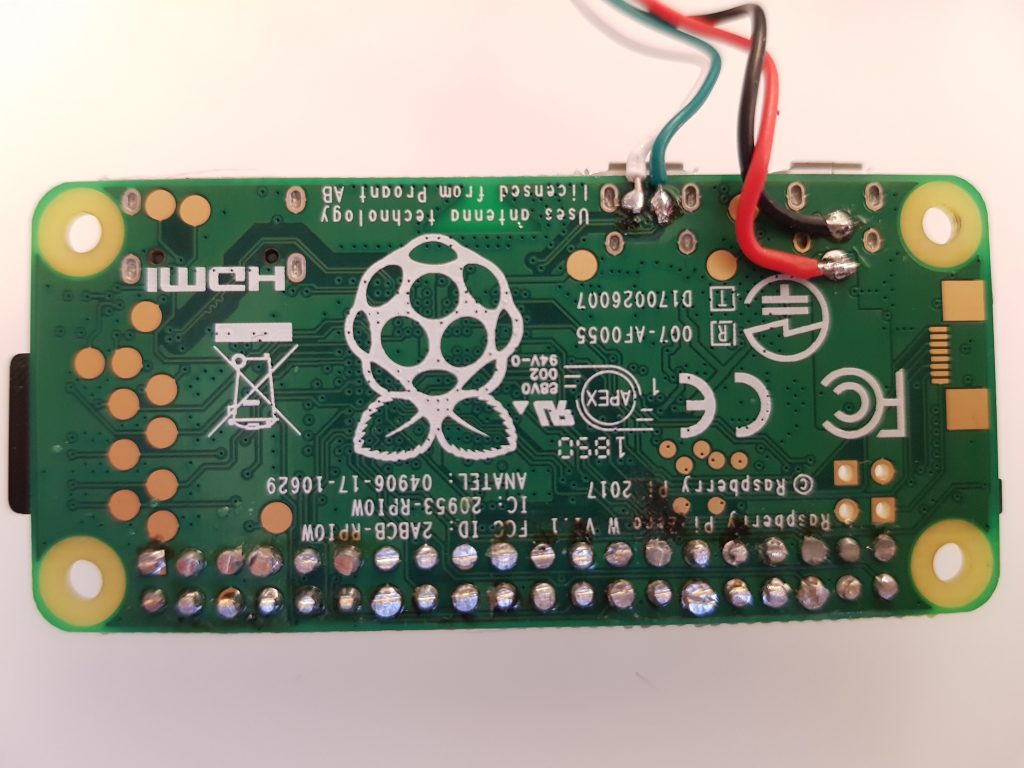

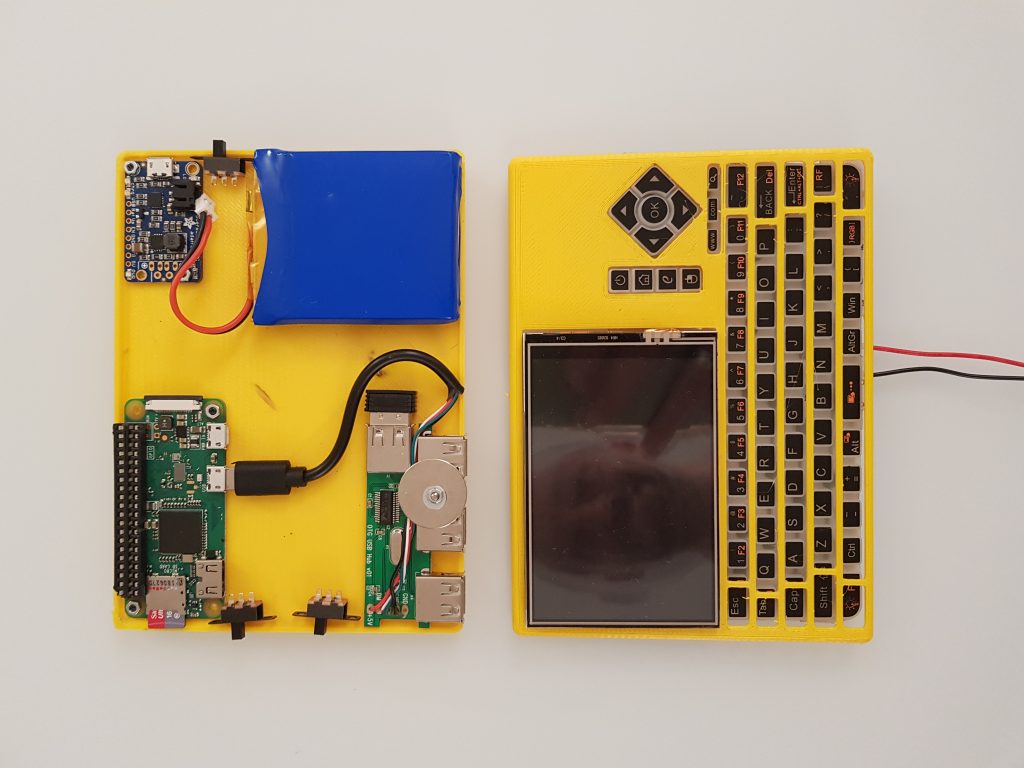

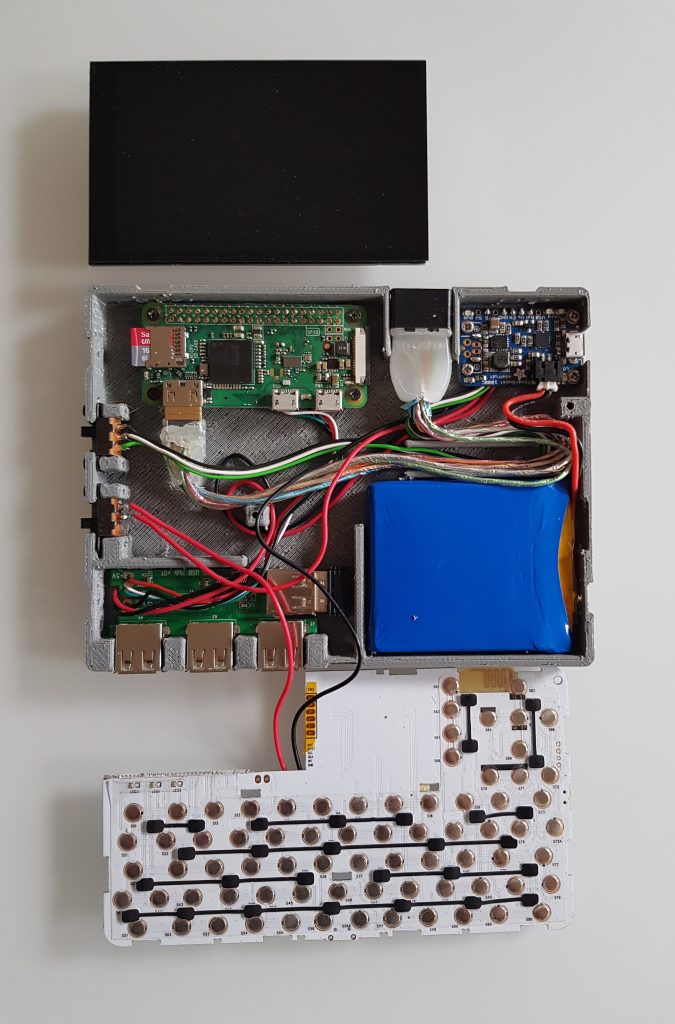

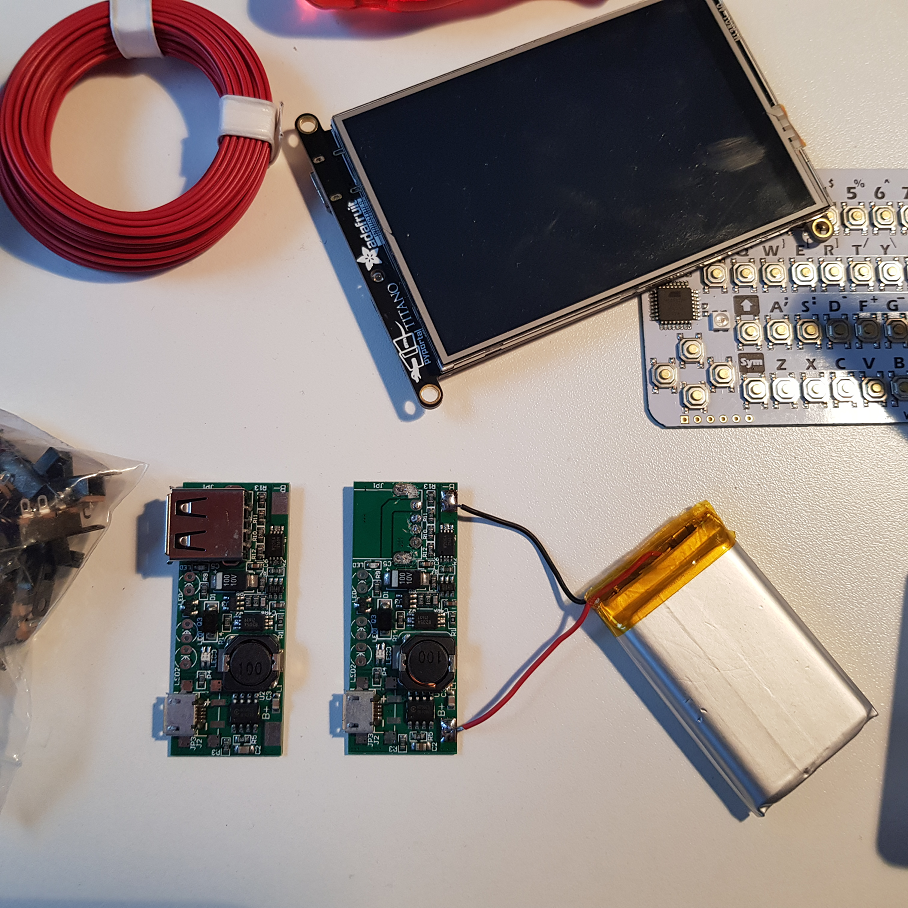

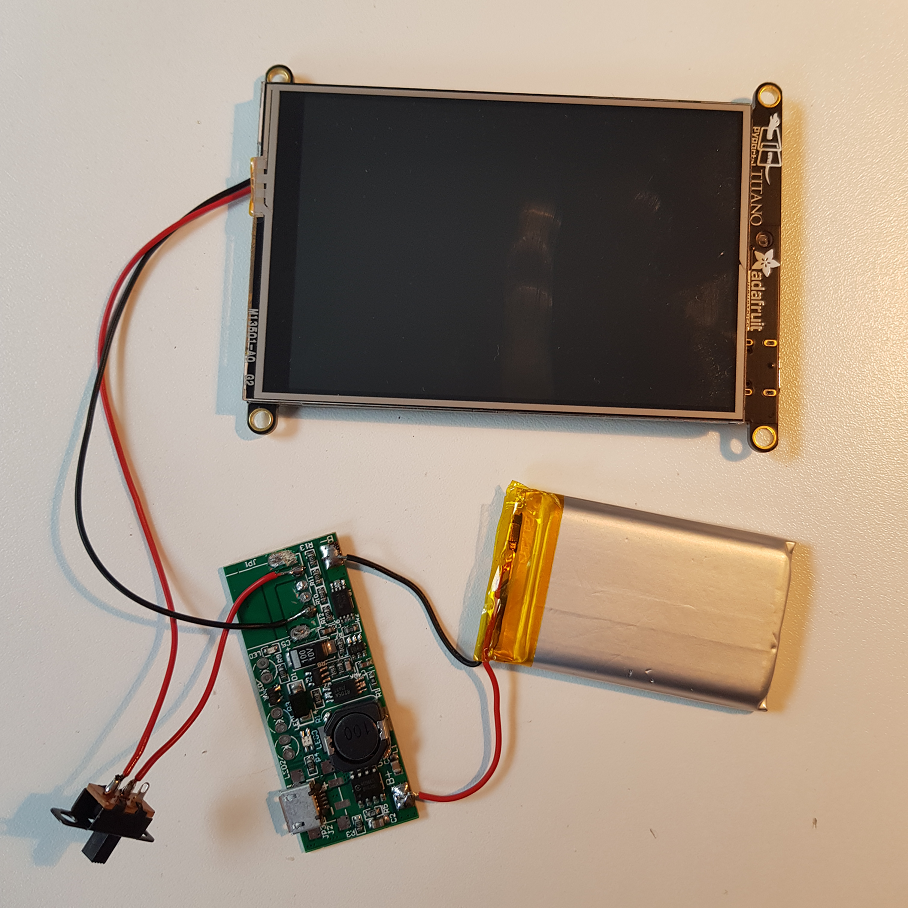

Next it was time to design the power source. This time I didn’t stick with the Adafruit powerboost, I think it is too expensive and it gets fairly hot. I had a couple of cheaper but larger charger boards in a drawer, so I decided to give them a go. To save height and space, I removed the USB plug:

To save height, I also removes the plugs from the pyportal and wired the power cable directly, following the wiring scheme from Adafruit:

Finally, I also removed the plug from the M5Stack keyboard and soldered the cable directly:

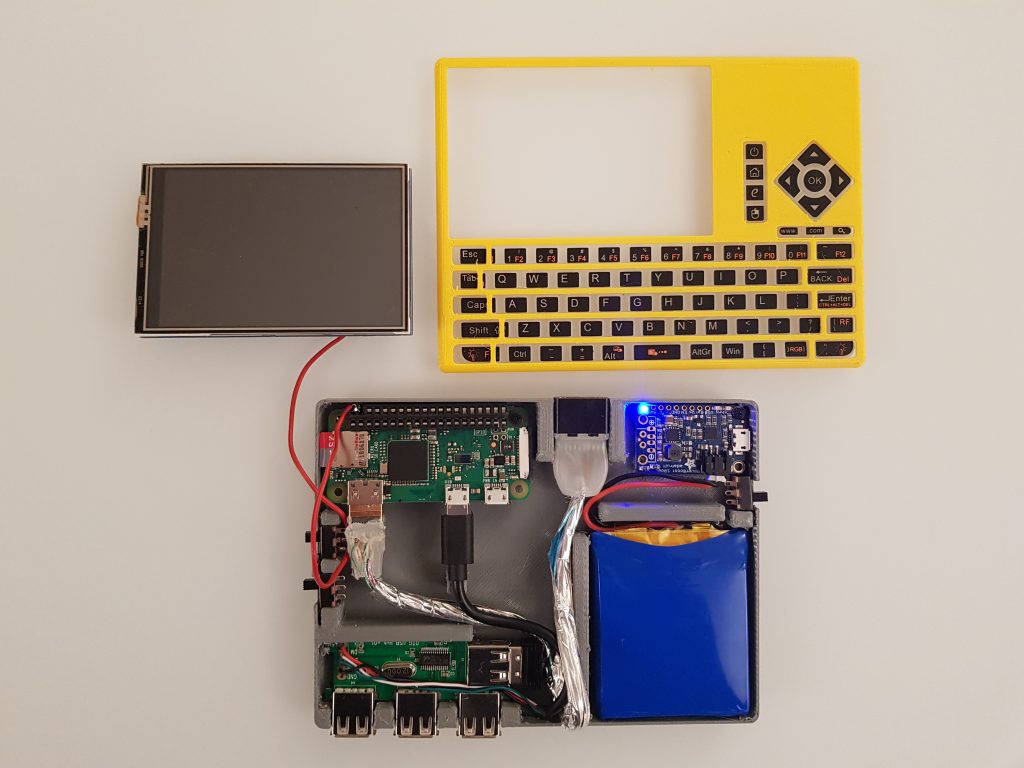

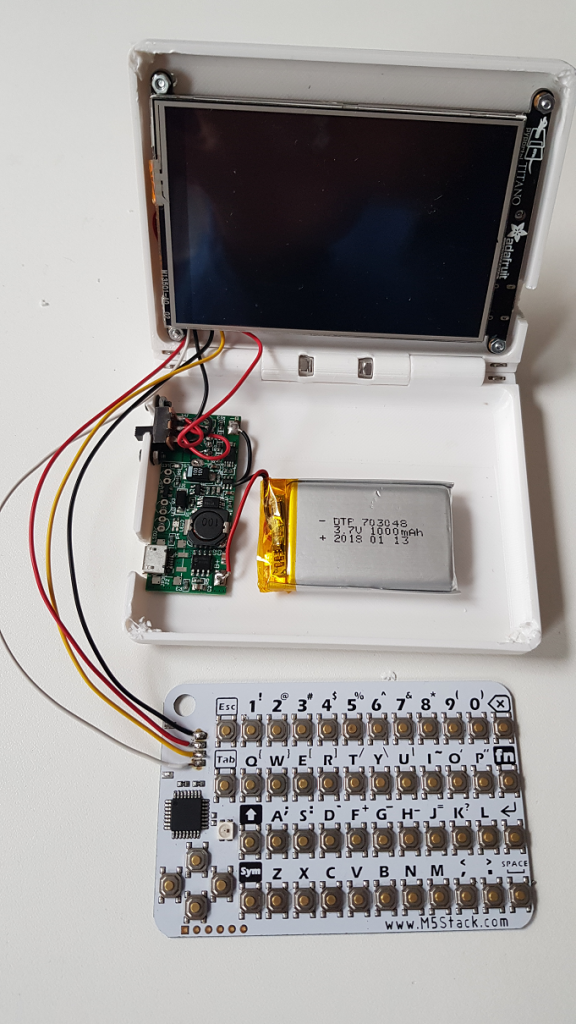

I had to modify a couple of places of the original case design and cut out the plugs for USB-C / pyportal, the power switch and the micro-USB charging port, then it was time to fit the power circuit:

Finally, the keyboard is added using a double-sided tape:

And now the little darling in action:

I wrote a little file lister in python as well as a minimalistic python editor. The problem at the moment is that you can’t write to the on-board flash when hooked up to a host using USB-C. Need to check out now whether it works when the device is battery powered. Stay tuned!

UPDATE: I just polished the case design to actually close properly and removed the magnet holders to give the innards enough space. Files are published on Thingiverse now.

UPDATE 2: This work was featured on HACKADAY!

/i/49335/products/2019-02-27T20%3A54%3A20.119Z-20190227_215059.jpg?1606306133)